back seal test flange|mechanical flange joint tester : Brand manufacturer Back seal testing. By using a unique patented technique KaMOS ® has developed a sealing arrangement for pipe systems which incorporates surveillance of flange conventions for all sizes. Resultado da 724K Followers, 56 Following, 355 Posts - See Instagram photos and videos from Cibelly Prof (@professoracibelly)

{plog:ftitle_list}

Download WWE SmackDown Shut Your Mouth game for Son.

Table B.57 and B.58 refer back to figure 19, which is a 9/16" AEHP port (30k rated port). You can use, 9/16" AEHP or 1/2" NPT (10k max WP, 15k max TP)for you flange. I would recommend using 9/16" port rather then NPT if you plan on using the flanges more then once.

american test kitchen vacuum sealer reviews

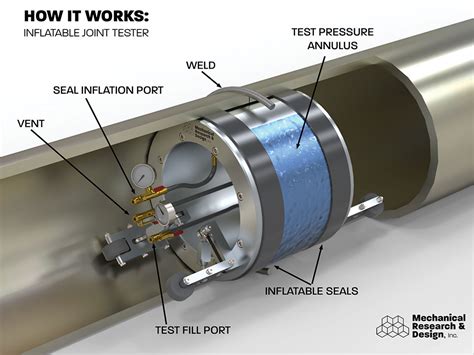

A flange tester is a leak and pressure testing tool that validates flange joint connections. One common type of flange tester, a flange weld test tool, is comprised of a bolt .Back seal testing. By using a unique patented technique KaMOS ® has developed a sealing arrangement for pipe systems which incorporates surveillance of flange conventions for all sizes.description. The BSTU provides a controllable pressure between 7 and 210 bar to be applied via. Manually Adjusted Pressure Relief Valve. Ram Operated Ball Valve (with reducing jet). Depth .

seal fast flange tester

A full range of standard flange weld testers are available up to 36” and compatible with common pipe schedules and flange configurations up to class 2500. Additional proven variations .TPC Clamp Connector seal ring for reverse integrity testing. The purpose of the reverse integrity test ring (or a back seal test ring) is to verify that assembly of the TPC Clamp Connector has been successfully performed, and that seal .

Ocean-5® BT01 is an ROV operated Back Seal Test Unit. The BT01 is designed to be easily mounted on Schilling Rigmaster manipulator and allows ROV to conduct pressure verification .Rapid Integrity leak Testing (RIT) safely and efficiently tests flange connections prior to operational start up, providing peace of mind and maximising production time.Ultrasonic testing can be used to determine if the flange face has been machined and if loss of sealing area has occurred. If there is no more seal to repair, the flange must be replaced, or the seal area must be renewed using a weld build .Reduce Downtime Fast and simple installation and testing Tests various types of flange weld connections, including weld-neck, slip-on, and lap-joint Suitable for use with a range of pipe schedules Minimal water use, less handling and waste Eliminates the need for a full system test Minimal Training Time Saving Cost Saving Adjustable spades to modify testing [.]

mechanical flange joint tester

Most common with cast iron or plastic flanges. Repair with a flange reinforcement ring. A flange that’s too low. Flanges that sit more than 1/4-inch below the finished floor can have this problem. Common when a non-plumber .

The principle applied in the leak test is based on pressurizing the annular space above and below the seal ring. If no pressure loss is experienced in this pressurization, the seal is deemed tight. The test pressure is applied to the annular space by drilling a hole through the flange into one of the annular spaces.

Test Pressure: Size Range: 3/4" – 24” NPS (DN20 to DN600) Flange classes 150# to 600# Higher flange classes available upon request Standard Seal Material: Urethane – a lternative materials available upon request Features. Improved seal-to-pipe Clearance: plug can be easily installed and removed even where there is severe weld protrusion

The Flange Weld Test Plug (FTP) by USA Industries simplifies the welding process by allowing you to monitor conditions, isolate and purge the weld area, and complete the weld and hydrotest to meet code requirements—all with one tool. The FTP features a high-lift seal that expands, providing a greater seal-to-pipe clearance. This eliminates the need to grind excess root .Internal weld testers can also be used to test the effective sealing of flange mounted ball valves. Dependent upon application, testers can be purpose manufactured to provide a specific length between the Posi-seals™. Flange weld testing can be achieved by either using the bespoke flange weld tester or by using an internal weld kat6787 Table B.57 and B.58 refer back to figure 19, which is a 9/16" AEHP port (30k rated port). You can use, 9/16" AEHP or 1/2" NPT (10k max WP, 15k max TP)for you flange.Understanding the function of these specialized flanges is crucial for effective fluid management and safety in various applications. API 6A Blind Flanges: These are used primarily to seal off a connection, offering a reliable closure for terminating pipelines, valves, or equipment. API 6A Test Flanges: Similar to Blind Flanges in function, Test Flanges come with an additional port.

The flanges seal when tightened bolts compress the gasket between the flanges into the grooves, deforming (or Coining) the gasket to make intimate contact inside the grooves, creating a metal to metal seal. An RTJ flange may have a raised face with a ring groove machined into it. This raised face does not serve as any part of the sealing means.Flange leakage is a serious problem in the Piping Industry. It has a tremendous potential to cause a severe hazard in plants. Hence, the possibility of leakage needs to be investigated during the design stage to reduce leakage possibility during operation. . Flanges are designed to remain leak-free under hydrostatic test pressure when cold .

The distance between the flange, washer, and seal assembly should be approx. 12”. If not, check to see both compression tubes are installed between the flange, seal, and washer assembly. Locate the flange to be welded on the pipe using an alignment tool (The Flange Test & Welding Plug is not designed to support or Bolting Sequence—proper bolting sequences must be followed to ensure even loading of the gasket.. Tightening Method — the installation and torquing procedures are important to the reliability and operational safety of flanges.Assuring a correct sealing force is applied and maintained will help avoid problems with flanges. Use of a torque wrench, .

When removing a toilet, replacing the wax ring between the bathroom and the floor-mounted toilet flange (commonly referred to as a closet flange) is essential. The wax ring’s purpose is to create a water and air-tight seal that can withstand years of use. This blog will provide a step-by-step guide on replacing a toilet wax ring and offer tips to ensure your project is executed correctly. The flange functions as a key intersection in this exhaust system. It is where many exhaust parts assemble and are intended to tightly seal. But occasionally, mishaps happen. When there is a hole or gap near this junction, there will be an exhaust leak on the flange. These gases escape through the leak as opposed to the correct pipes and mufflers.Flange Weld Test Plugs Isolate and Hydro Test Flange Weld Joint, with one device, quick and easy. Steam, Sniff, Purge, Weld & Test. Skip to content. 1-800-668-9875. Search Search. . Improved Seal-to-Pipe Clearance: Plug can be .

and secondary seals. 4 Pressure Monitoring Pressure changes within the sealed recess are monitored from outside the flanges via the test equipment. If the seal is sufficient, the pressure will be maintained. Conversely, in the event of a seal fault, failure to hold the pressure can provide an indication of a leak path between the gasket and the

Ensure that the seal is centered over the sewer pipe flange and that the toilet is properly aligned with the closet bolts before pressing down to compress the seal. Regular inspection and maintenance : Periodically check your toilet for signs .Flange Gaskets. A flange gasket is a gasket made to fit between two sections of pipe that are flared to provide higher surface area. While flange gaskets appear to be one of the simplest types of sealing components, the impact of poor quality (gasket material or gasket manufacturing), incorrect selection or installation is only realised when your installation begins to leak or worse, .For Flange ANSI Class. 150. 300. 600. 1500. 2500. Material. Aluminum. Carbon Steel. Copper. Graphite. . Seal irregular shapes and tiny crevices by applying a bead that hardens into a gasket . Seal gaskets on metal parts. 8 products. Raw Materials. Rubber. Compresses and bounces back to shape; often used for sealing, cushioning, and shock .SAE Flange Seals provide high functional security and can easily be mounted and dismounted. They are used in a variety of applications including hydraulics, press manufacturing and materials-handling. SAE Flange Seals corresponding to SAE J 518 are available in three different variants: O-Rings, Rectangle Seals and Zurcon® Flange Seals DRV5.

When replacing a toilet or resetting an existing toilet after a repair, it's important to set the correct toilet flange height to ensure a good seal and prevent leaks. You want to make sure the toilet sits level and does not rock on the floor, as this can compromise the seal. Toilets are sealed to the floor flange with a wax ring, but the height of the flange and the tightness of .

I Put the One N Done Toilet Seal to the Test: Here’s Why I’ll Never Go Back to Traditional Seals! By Kurt Valdez. . The rubber material of the seal creates a tight, waterproof seal around the toilet flange, ensuring no water leakage. – Long-lasting: Unlike traditional wax rings that need to be replaced every few years, the ‘One N Done .Rapid verification of joint integrity prior to start up saves time and provides peace of mind. The Alba-RIG™ is designed to be used in Ring Type, Raised Face and Flat Face flanges. The Alba-RIG™ - Is fast and easy to install removing complexity and costs Giving choice and flexibility in test equipment and processMachining the flange face in the field is performed as an in-situ repair. Ultrasonic testing can be used to determine if the flange face has been machined and if loss of sealing area has occurred. If there is no more seal to repair, the flange must be replaced, or the seal area must be renewed using a weld build-up technique.

Seal Quality Test Methods. Seal Quality Tests . •Well-closed caps are less likely to back-off during product life-cycle and leak . •Vials, bottles, cartridges with stoppers having a land-seal flange, closed with aluminum caps Seal Quality Tests 19.Hydraulic drive clamp claws to hold blind flange at the end of valve flange to have a performance test. . It is suitable to have a shell, seal and back seal test for flanged end valves. 2. No external force affects test valve as clamp hold flange. 3. Right work platform can be turnover 90 degrees to have air seal test. 4. Test medium is water . Follow kit instructions to install flange extender or new flange. Ensure proper alignment. Use concrete screws to securely fasten flange to floor. Reinstall toilet and seat. Apply plumber’s putty around base. Turn on water supply and test for leaks. Be patient through this process and take time to get the flange perfectly aligned and secured.

webSéculo Adega. 8,582 likes · 1 talking about this · 82 were here. Distribuidora de bebidas com loja de varejo, em Maringá.

back seal test flange|mechanical flange joint tester